Sectors involved

Stakeholders

Resources

Annual energy use

GWh/year

Overall concept of the demonstration activities to be implemented

The proposed demonstration deals

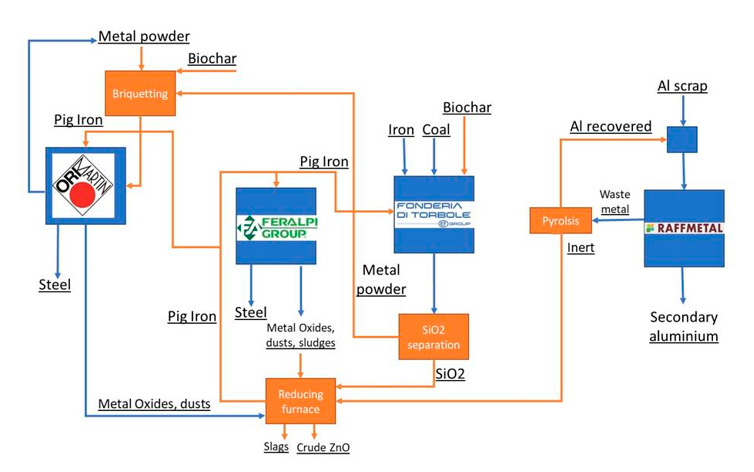

The proposed demonstration deals with the development of a framework for establishing an industrial symbiosis (IS) network in the Region of Brescia.

To this end, residues produced in a total of 4 companies will be treated with technologies already studied and validated under relevant conditions, so they can integrate pilot units that demonstrate the feasibility of the collaborative scheme for transforming industrial residues into raw materials for others or, eventually, recycled internally.

By-products from steel, cast iron and secondary aluminum production will be treated through the introduction of 4 novel technologies to recover metal, while interaction with rural communities will be fostered in order to analyze bioresources that could replace carbon fractions at these companies.

The overall proposed scheme is provided in the following Figure.

Energy efficiency

Energy intensity

CO2 emissions

Raw materials intensity

Waste generation

(metallic powder)

The overall demonstration will require the design and installation of

The demonstration activities to be performed at Brescia will be supported by a mapping activity that will start by collecting data about every possible pathway inside the territory for providing industrial resources without making use of virgin materials.

This step includes not only the input-output of industrial sectors but also the needs and residues for other territorial activities such as public services, recovery of contaminated sites, etc. Finally, a replication analysis for the use of slags as alternative raw materials will be performed within CORALIS, together with an assessment regarding the potential interaction of the waste heat recovery systems at Brescia region with the district heating and other potential uses for the recovered heat under an IS scenario.

Description of the demonstration readiness level towards Industrial Symbiosis (IS)

All planned demonstration activities are foreseen in this area including, as mentioned earlier in this section, the following technologies:

Main challenges to be addressed and barriers to be overcome

The main challenge is to coordinate the logistics, needs and required interactions among the various value chain actors in order to cover the production demand without affecting the availability and quality of product.

To this end, Brescia demonstrator gathers several stakeholders that can strongly interact in order to maximize the positive effects of an intersectorial approach.

The main barriers to be overcome are:

Equipment to be installed, modifications required and relevant activities for each stakeholder involved

RINA-CSM

IS facilitator: Chemical and physical characterization of the selected wastes (e.g. Chemical analysis, leaching test, phase distribution, thermophysical properties), definition and the operating conditions of the pre-treatments (briquette production) to be applied to such wastes. Preliminary phase of the preparation of the testing materials, performing heat and mass balances in industrial trials.